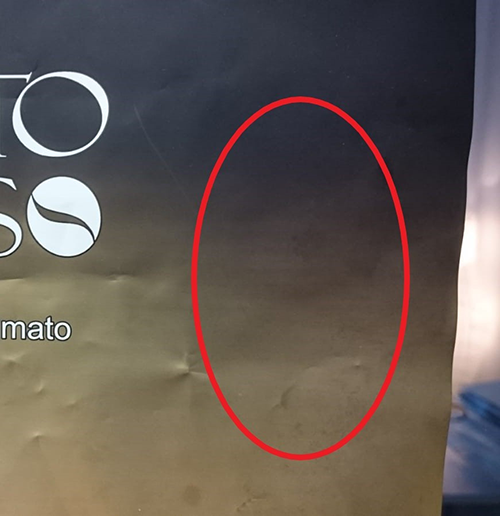

Flexo printing

Ink Spitting

Ink that passes under the doctor blade and splatters onto the substrate being printed. Most common in Flexo with UV ink.

Causes

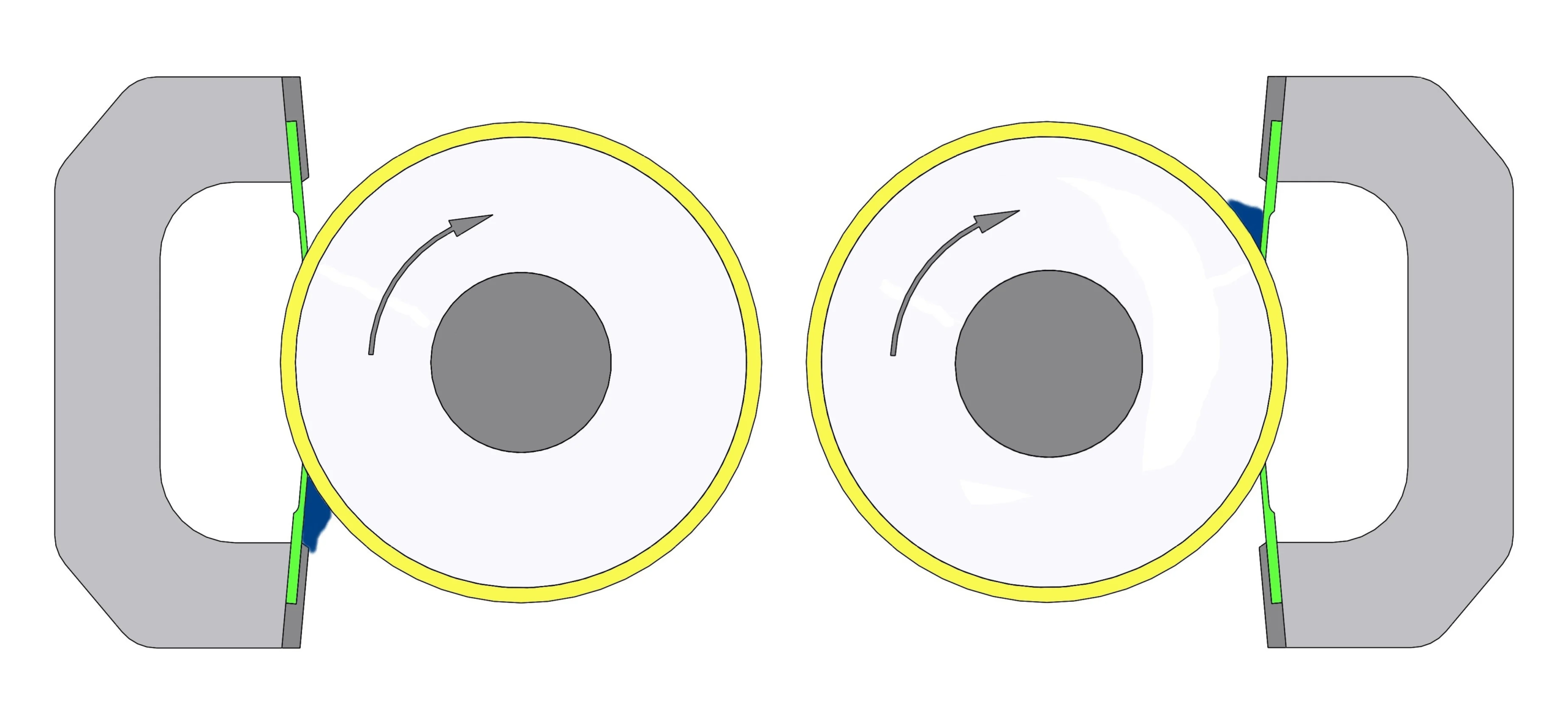

- Doctor Blade contact zone too thin

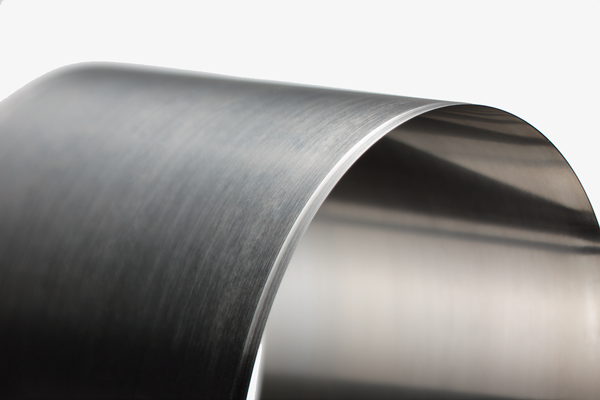

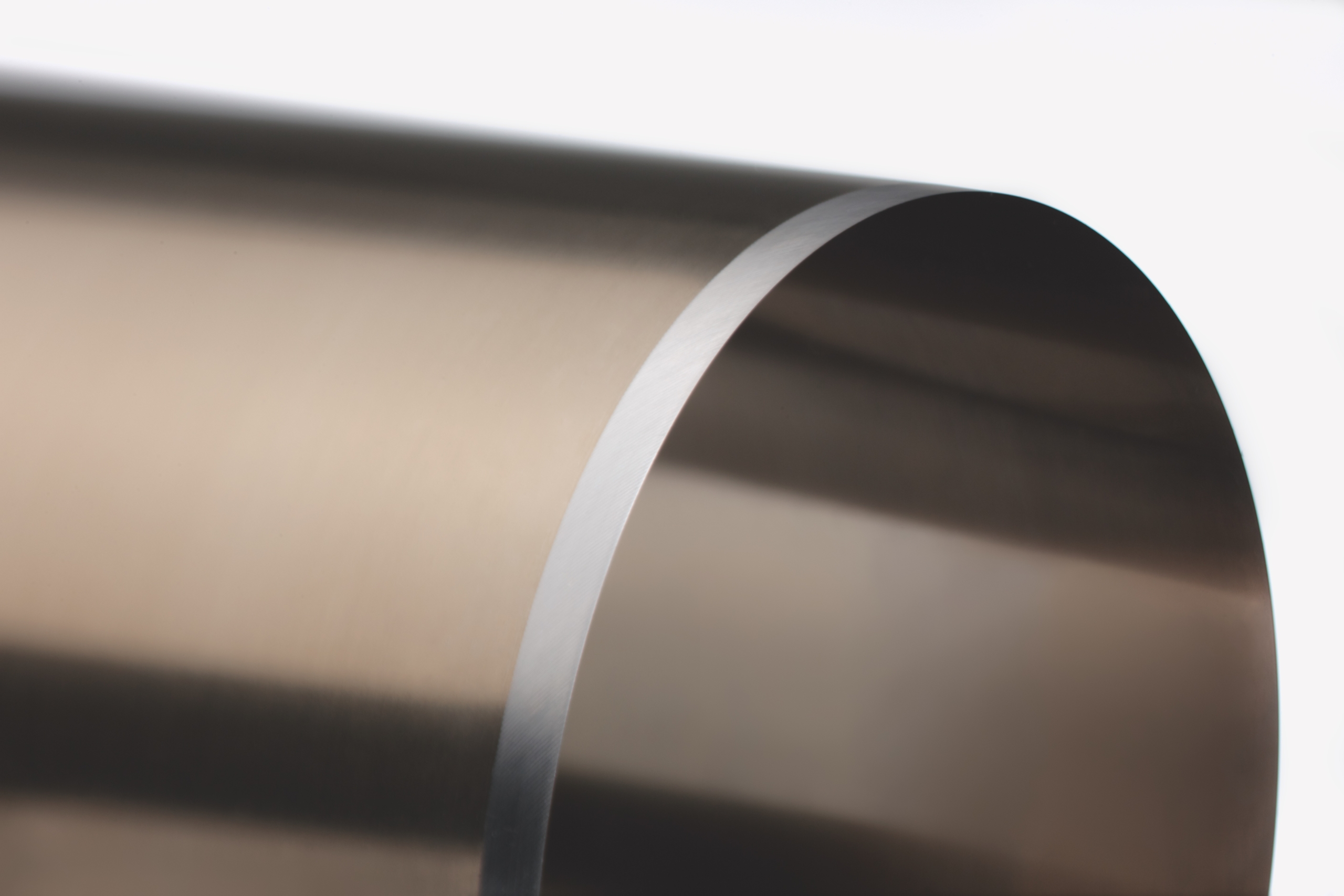

- Doctor blade too thin

- doctor blade pressure too low

- using the wrong doctor blade