Particularly in the difficult times in which the print media industry has been experiencing for some time now, long knife life, low knife changing costs and low grinding costs are important parameters in postpress (with regard to guillotines, three-knife trimmers, trimmer knives and spine tools). These parameters significantly influence the cost structure and thus the unit costs, which are used as a productivity indicator. At the same time, the cut must be of the highest quality so that customer complaints are ruled out from the outset.

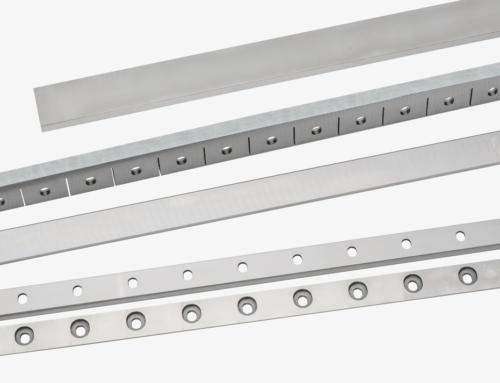

Several qualities

TKM products are available in various qualities (standard steel, high speed steel, powder steel and various grades of carbide) for every application. In addition, coated knives are supplied for special requirements, e.g. adhesive products such as labels. Only the correct adjustment of the cutting tool to the product to be cut makes it possible to achieve an almost perfect cut and to extend knife life. A flexible and sustainable sharpening service is decisive for the customer’s operational reliability. If the grinding service achieves service life and cut quality of new knives, one can speak of reproducibility of the original tool.

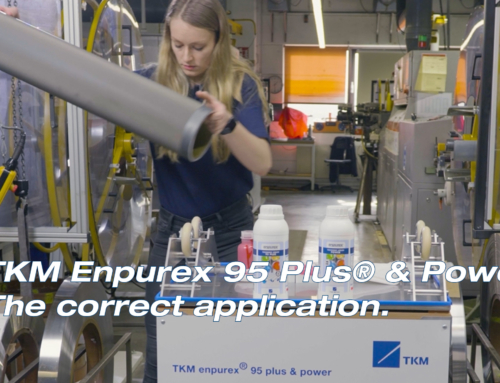

Service is top priority

TKM has long been offering an integrated service. In a first step, the current situation (what is being cut, how often is the machine in use, what are the replacement intervals today, what is the reason for blade replacement, etc.) is illuminated and analyzed together with the customer. In a second step, products and qualities are recommended which are explicitly adapted to the intended use. The aim is to always find and offer the right knife quality at the best price-performance ratio together with the customer. In this way, spare parts and maintenance costs can be reduced and knife service life can be significantly extended. According to TKM experts, so-called leasing systems offered on the market are often too rigid and only cause higher costs, especially in times of low capacity utilization.

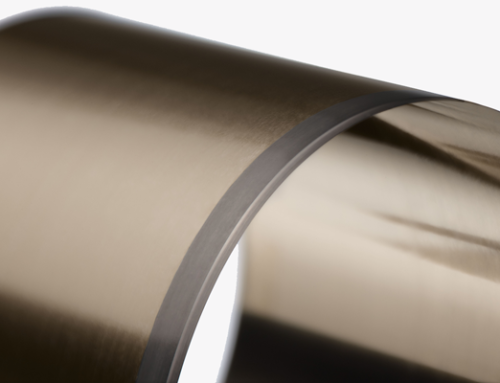

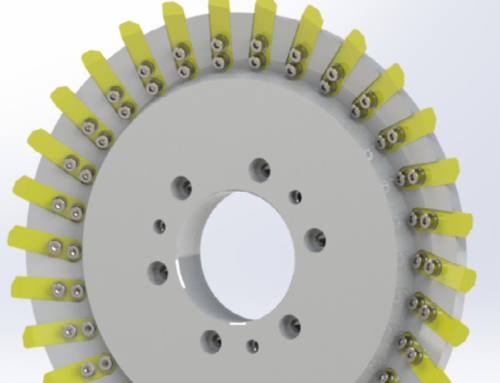

New sharp edge

Cutting qualities are primarily achieved by geometric conditions such as tolerances, surface roughness depths and angles. The choice of knife quality primarily influences the tool life. A perfect cut can only be achieved if the knife quality and the requirements for the cut quality are coordinated. The aim is to reduce the contact between the knife and the material to be cut to a minimum. The TKM Group offers a special feature with its self-developed “New Wave” or “Hyperwave” cut, an idea inspired by the Razor Blades and implemented in the form of its own technology. A thin cutting edge reduces dust formation and improves the flow of material. The “New Wave” or “Hyperwave” products significantly reduce friction between the cutting tool and the material, resulting in longer tool life and better cut quality. The TKM experts will be happy to advise interested parties – and perhaps together we will succeed in achieving the perfect cut.

Text: TKM / bindereport