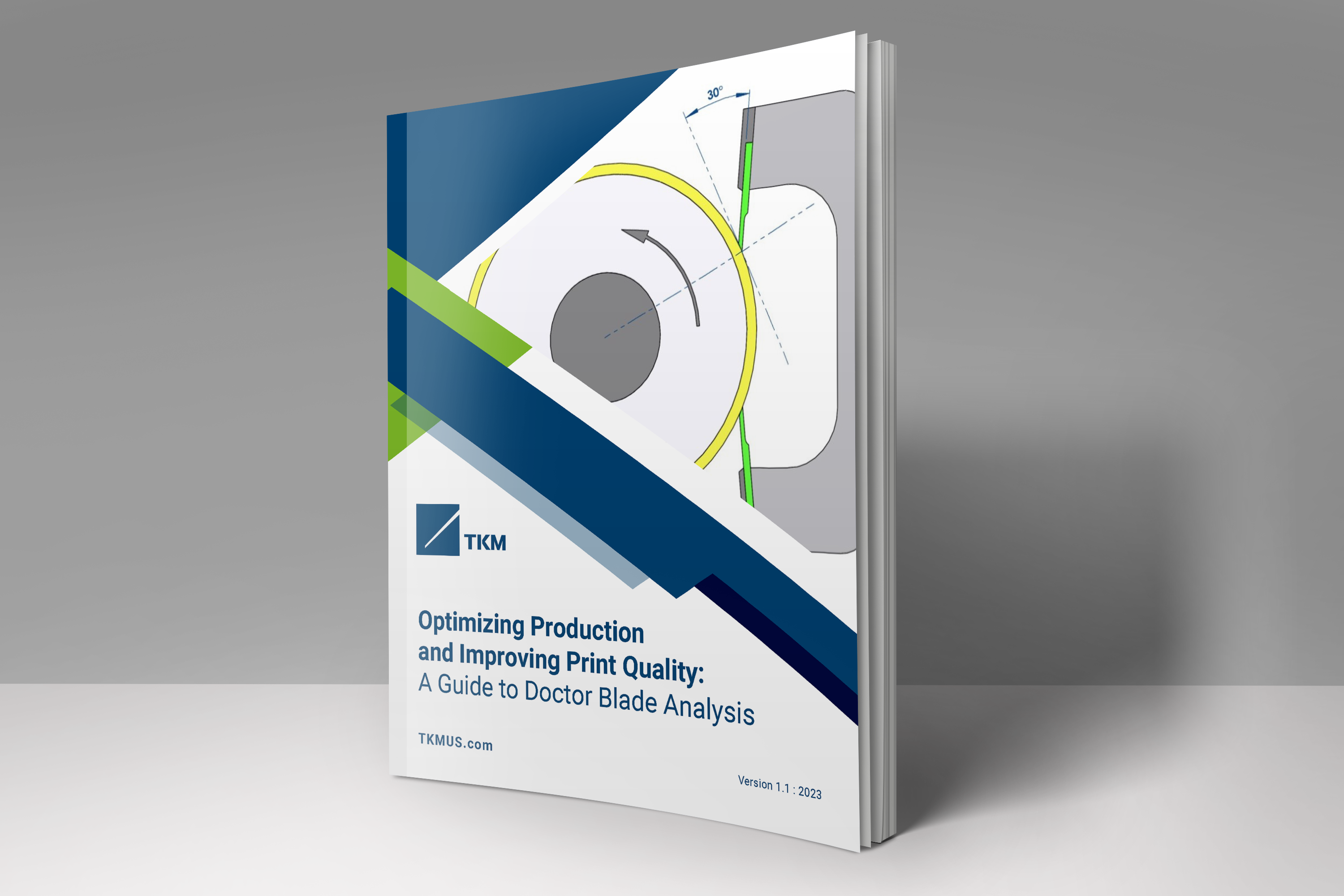

Doctor blade analysis is an essential aspect of flexographic printing that plays a crucial role in the quality and efficiency of the printing process. Doctor blades are thin, flat metal or plastic blades used to remove excess ink from the anilox roll. Proper analysis of doctor blades can help to optimize production schedules and improve print quality by ensuring that the blades are working effectively.

One of the primary reasons why doctor blade analysis is important is that the pressure of the blade on the anilox roll can have a significant impact on the printed product. If the blade is not properly aligned, it can create an uneven contact area with the anilox roll, leading to inconsistent ink distribution and poor print quality. On the other hand, if the blade is applying too much pressure, it can result in excess ink being deposited on the printing plate, leading to wasted ink and substrate and reduced print quality.

Proper blade alignment is essential to ensure optimal wiping action and consistent ink metering. By finding the balance between minimal pressure for wiping action and sufficient pressure for metering, printers can maintain optimal performance from their doctor blades.

Another reason why doctor blade analysis is important is that chamber misalignment can also impact the performance of doctor blades. If the chambers are not properly aligned, the blade may not be able to apply even pressure on the anilox roll. This can lead to issues such as ink leakage and blade wear, which can result in higher costs and lower print quality. To ensure proper chamber alignment, it is essential to regularly check the chambers and adjust as necessary.

Blade wear is another factor that can affect the performance of doctor blades. As blades wear, they can become less effective at removing excess ink and controlling the pressure on the anilox roll. To optimize production schedules and improve product quality, it is essential to measure blade wear and replace blades as needed. There are various methods for measuring blade wear, such as using a protractor, caliper, or a microscope.

In conclusion, doctor blade analysis is an important aspect of flexographic printing that plays a crucial role in the quality and efficiency of the printing process. By properly aligning doctor blades, maintaining proper chamber alignment, and replacing blades as needed, printers can ensure that their doctor blades are working effectively to provide the best possible results.

If you would like to learn more about the analysis of used doctor blades and how blade wear can impact production, we encourage you to download our Doctor Blade Analysis White Paper. This document provides a comprehensive overview of the issues discussed in this description and offers solutions to ensure proper blade alignment and optimize production schedules. Don’t miss the opportunity to improve your understanding of this critical aspect of flexographic printing. Download the Doctor Blade Analysis White Paper by clicking below!