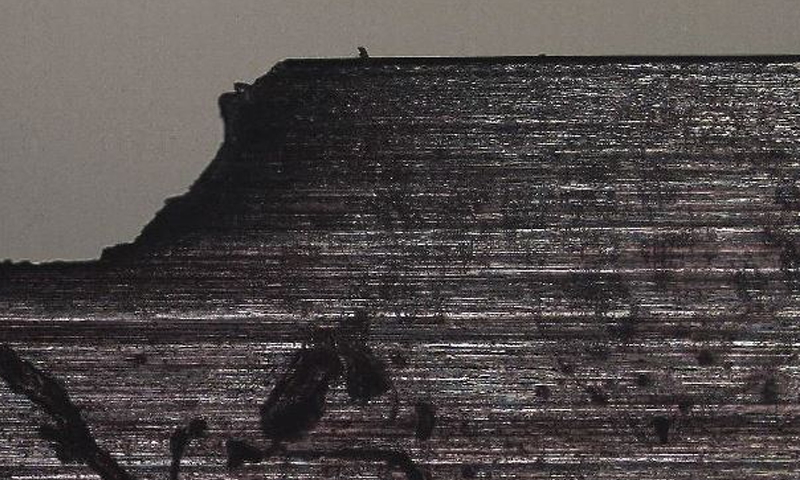

Gravure

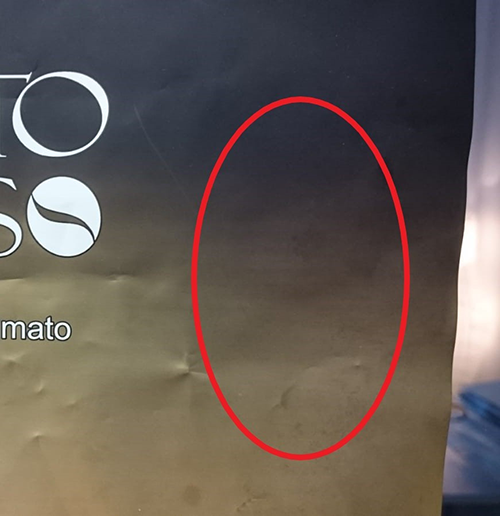

Missing Dots

The ink from some engraved cells do not transfer to the substrate.

Causes

- Dirty or insufficient electro static assist (ESA)

- Wrong ink viscosity

- Doctor Blade angle too steep

- Doctor Blade tip too thin, Dirty

- Damaged or old impression roller