Gravure

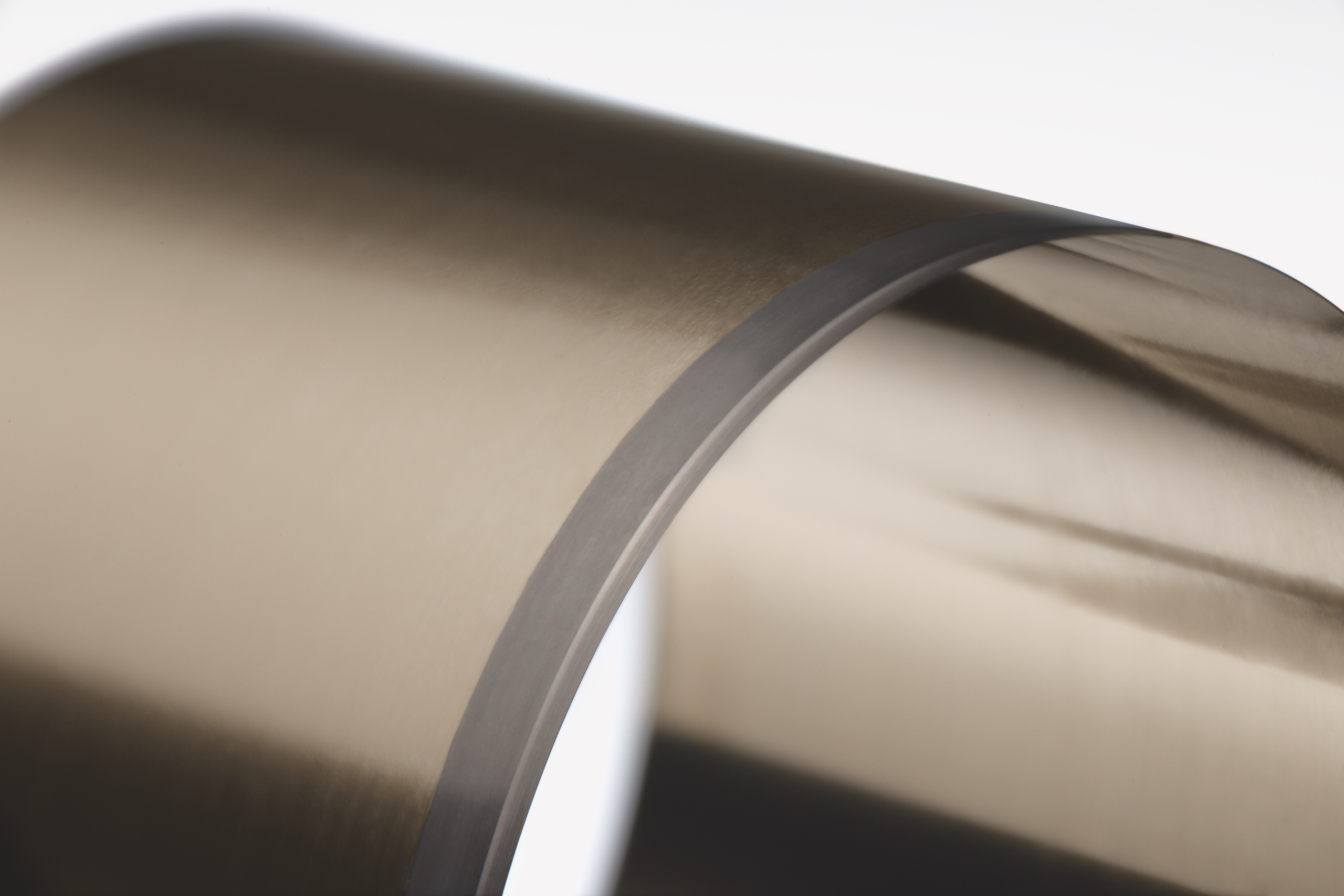

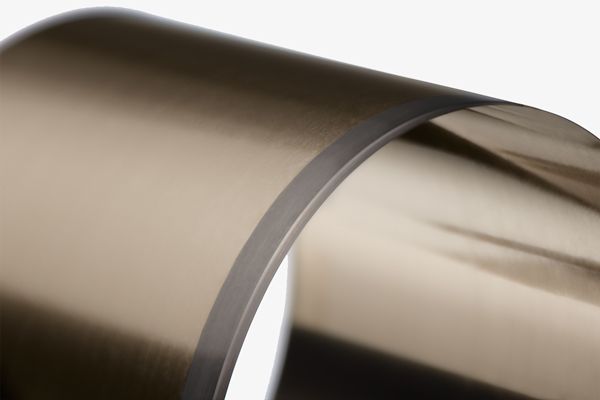

Hazing / Toning

Ink showing in non-engraved areas in various intensity. This could range from a light haze that is barely detectible, to a heavy noticeable ink appearance. Hazing / Toning is the most common printing defect for gravure.

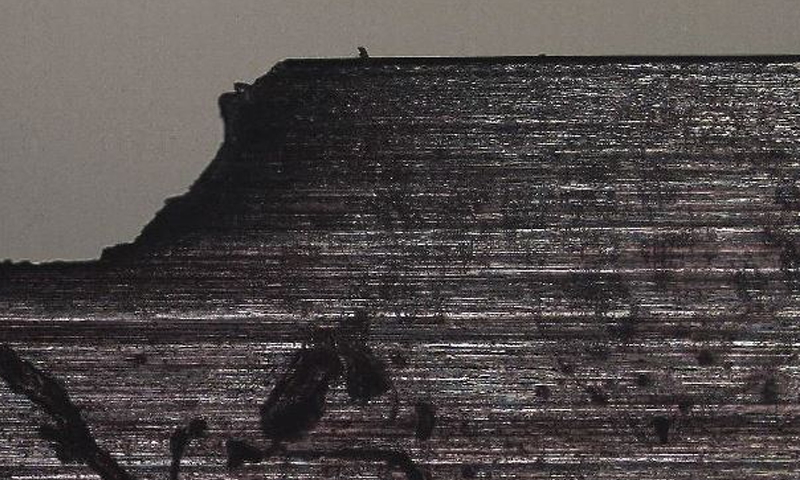

Causes

- Not using a ceramic coated Doctor Blade

- Blade angle too flat

- Ink is not drying fast enough

- Wrong ink viscosity

- Incorrect roughness of the cylinder (Rz)

- Wavy Doctor Blade