Illustration printing

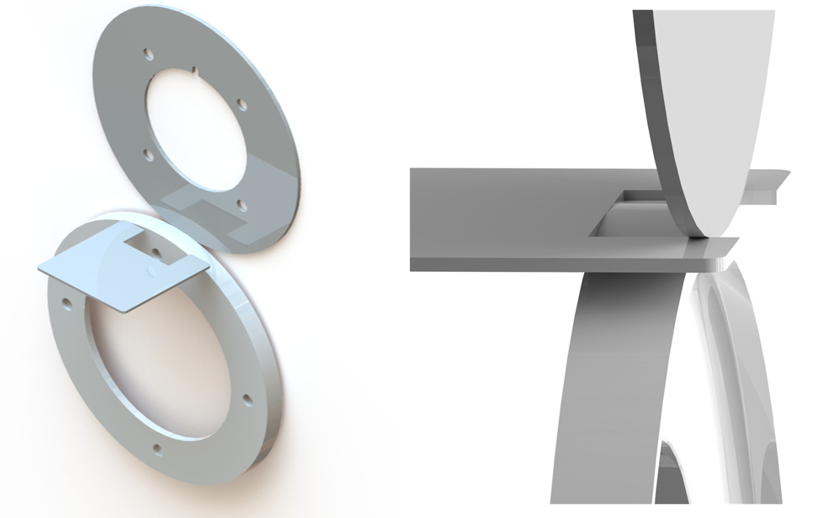

The correct overlap

Problem case

- Overlap is too high:

If the slitter dip too deep the cutting point and speed of the slitter is changing, as it will be driven by the friction with the anvil. Both will lead to more dust formation, higher wear/lower durablity. Worst case scenario is a ribbon break. - Overlap is too low:

If the slitter is interleaving too little, the risk is high that the slitter is breaking and that the knife may jump on or over the anvil. Furthermore, due to the wrong cutting point it will lead to more dust formation.

Solution

How can you avoid an overlap, which is too low or too high?

- Exact setup of overlap

Recommendation:

As a rule of thumb the overlap should be 1 mm

Tip:

Use our free setting tools and our calculation app